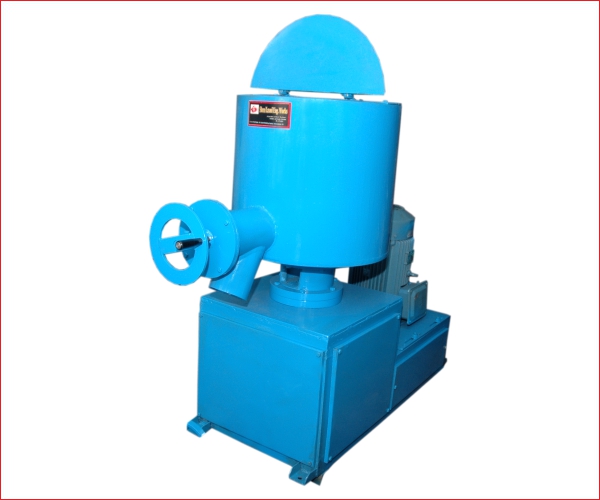

We offer Masterbatch Mixer Machines with superior quality at cost-effective prices. These machines are manufactured by incorporating the latest technology.

Shree Laxmi Engineering works specialize in manufacturing and supplying of heavy-duty constructed Masterbatch Mixer Machine. This mixer is appreciated widely among our clients for durability, performance and efficiency. The comfortable discharging arrangement and smooth operation make it a preferred choice over the available substitutes in the market. Low on maintenance, these mixers are used heavily for color mixing and preheating all kinds of plastic material. Tabulated below are some of the key specifications of our range of Mixers machine:

| TECHNICAL SPECIFICATION | ||

| Inch | Motor | Output |

| 20” | 7.5 HP | 25 kg/bags |

| 24” | 12.5 HP | 50 kg/bags |

We are manufacturer all-important plant components in in-house so that we can give you very tight control over the quality of the products. We have designed the best quality of Masterbatch Mixer Machine, which is authoritatively used in variant industries like mixing powders, pastes, pigments and granules with the proper addition of liquid.

Shree Laxmi Engineering Works, we are continually working to satiate the needs of clients regarding the industrial Masterbatch Mixer Machine.

Plus we precisely manufacture the products suiting the specifications of machinery that are being utilized in their industries.

Some Masterbatch Mixer Machine is also known as plastic scrap mixer machine and granules color mixer machine.